Our Work

Photo Gallery

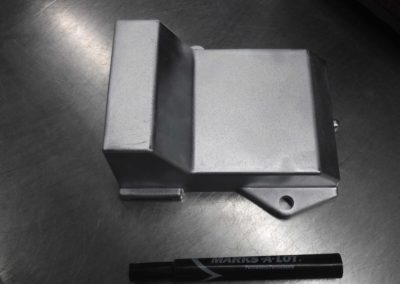

For more than 60 years, ALBCO Foundry and Machine has produced premier non-ferrous sand and graphite permanent mold castings for OEM and aftermarket replacement parts. It’s always been our mission to help you reduce costs while enhancing your product’s performance, appearance and quality through process validation and sound manufacturing. See ALBCO in action and browse through our photo gallery to stay current on our latest castings.

Like what you see? Request a quote today and discover how ALBCO can provide you with a superior and cost-effective solution.

Casting

Graphite Permanent Mold

This form of casting works best with zinc-aluminum (ZA) alloy, ZA12. The graphite permanent mold process offers superior design flexibility over traditional forms of casting. ZA coupled with permanent mold provides cast-to-size accuracy that can greatly reduce or entirely eliminate machining and secondary operations. It is the preferred choice over die casting because of lower quantities and lower tooling costs.

Sand Casting

The most common casting process available today. A preferable choice for low volume production or few castings, but is suitable for any quantity, even for very high production using automatic molding equipment. Tolerance capabilities are limited, therefore secondary machining is usually required.

Your success is our mission. Let’s talk and see how ALBCO Foundry can mold your next vision into a reality.